Decarbonization is the main driver for our land-based and maritime applications.

With a circular economy model in mind, we support lower GHG emission through advanced technologies for the production of biofuels from landfills, farming and organic waste.

We also contribute to the reduction of the environmental footprint of traditional oil&gas sources, avoiding the need for flaring and turning waste gases into ready-to-use energy.

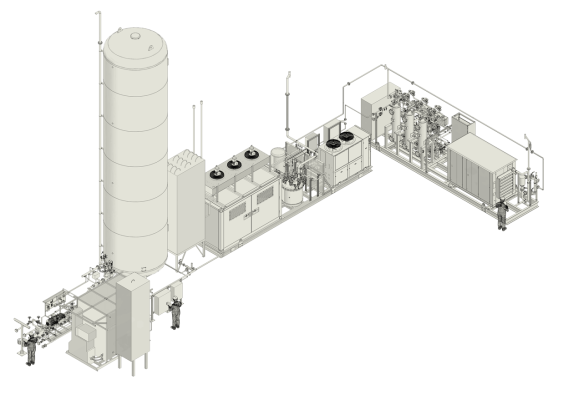

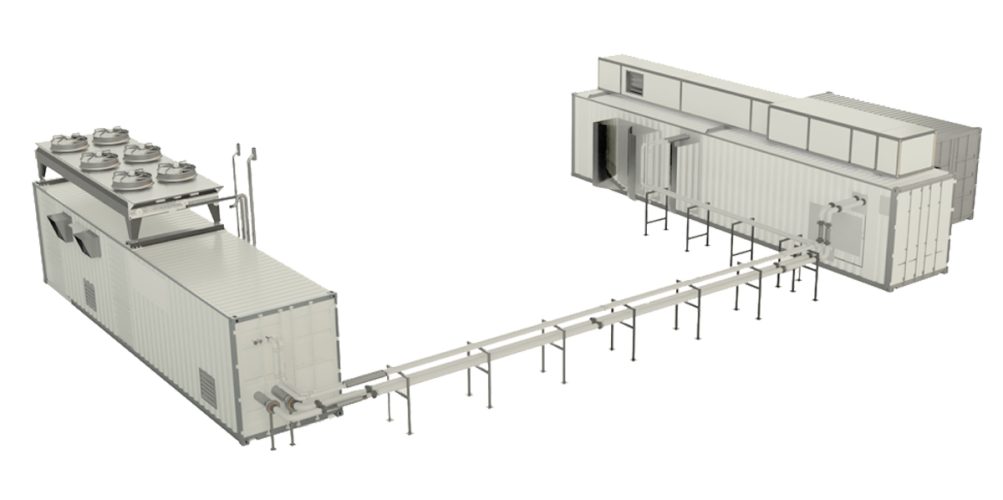

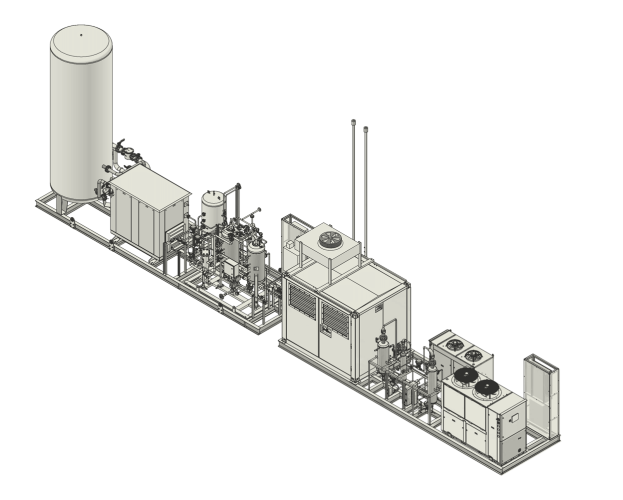

Ecospray micro-liquefaction systems, starting from 2 tons / day, are easy to install, modularized, skid-mounted and containerized. Customized solutions are also available, based on the specific production needs of the customer.

The process is based on the compression and expansion of methane or biomethane to reach the temperatures of liquefaction without using nitrogen or other refrigerants, thus making the solution independent from third parties.

Our advanced solutions for power generation and sustainable fuels allow converting any existing biogas plant into a system that produces bio-LNG, making it economically sustainable and profitable.

Ecospray can supply the entire biogas value chain, from pre-treatment and biogas upgrading to bio-LNG distribution, including a modular and scalable model particularly useful for those plants located away from the main pipelines.

The natural gas liquefaction solution allows on-site production from pipeline, avoiding the transport of LNG from large storage terminals, significantly reducing logistic costs, unforeseen events and further emissions associated with road transport.

At the same time, the associated gas (APG) can be directly converted into LNG, transforming the wasteful gas flaring into a resource. Our compact, plug-and-play solution is easy to install and can be quickly relocated, if needed.

The CO2 liquefaction is the technology that completes Ecospray’s suite of decarbonization solutions.

With the storage system, the CO2 liquefaction can be configured as a standalone system or can be completely integrated with the biomethane liquefaction from the biogas upgrading module, providing a truly carbon negative fuel.

The liquefied CO2 can be used in the industrial and food sector, thus closing a virtuous circle.

Do you want to know more about our Liquefaction Technology and stay updated with our Industry & Renewables Solutions?

Fill the form and download the latest version of our Liquefaction Map.