CatEMission design, develop and manufacture emission reduction solution packages for the Off Road, Industrial, Construction and Marine Industries.

We are a joint venture between Ecospray and Europe’s leading catalytic emission products manufacturer.

This combined experience gives us a unique market position, whereby we can provide full-service emission reduction packages for the Off Road, construction, industrial and marine markets.

Emission reduction solutions include:

Based in Northern Italy, we have the benefit of onsite substrate manufacturing/coating, R&D, bench testing and the latest steel fabrication equipment. This enables CatEMission to have complete control over all processes, these combine and offer flexibility, the latest tested technology and reduced lead times for our clients.

We work closely with clients to fully understand their requirements to provide a cost effective, durable emission reduction solution which can be designed to meet the latest European MCPD and NRMM directives including Stage V emission levels for stationary engines or IMO Tier III and EPA Tier 4 for Marine applications.

Understanding that different clients have different demands and requests is paramount, so we do not supply “off the shelf” products. Due to our unique structure, we can be as flexible as needed and still deliver our products in line with client’s expectations.

SCR systems produced employ DeNOx catalysts and have a unique designed reagent mixer system. These are widely used in the Marine or Industrial markets to keep system designs as compact as possible and so that clients can be compliant with more restrictive NOx regulations, such as IMO Tier III or EPA Tier IV and NRMM Stage V.

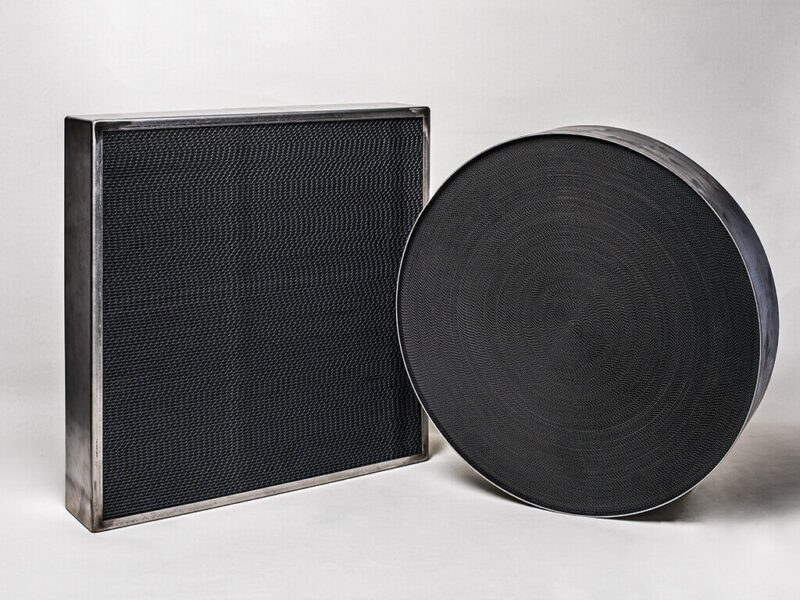

Metallic substrates used have high abrasion, strong mechanical resistance, and a long operation life.

Diesel Oxidation Catalyst (DOC) is a honeycomb catalytic converter, constructed by either ceramic (cordierite), silicon carbide (SIC) or metallic foil. DOC is especially designed to promote oxidation of exhaust gas components by oxygen already present in diesel exhaust gas. This then oxidates Carbon monoxide (CO), Hydrocarbons (HC), Diesel particulates Organic Fraction (OF), as well as aldehydes or PAHs. (Where DOC is used to remove organoleptic emission, it is called VOC).

The Diesel Particulate Filter (DPF) removes particulates from Diesel engine exhaust gas through physical filtration with a honeycomb filter made by either Ceramic (cordierite), Silicon Carbide (SIC).

PMF (Partial Metallic soot Filter) is an alternative to the DPF acting as a particulate reduction solution for a wide range of applications where space, cost or design complexity makes a full DPF installation not viable. PMF can be modular and flexible to suit any engine size, which operates at any temperature, with any fuel.

DOC, DPF and PMF systems are suitable for pneumatic and thermal cleaning.

MSC Methane slip Catalyst is a catalytic converter that reduces the Methane slip from the engine emissions. As commonly understood, Methane has a higher harmful potential in relation to other GreenHouse Gases (GHGs) and substrates can oxidate the residual Methane at the engine outlet, with efficiency up to 95%.

Remarkable technologies aren’t just reliable and performing systems: in fact, we skip one generation of technology and go to market with the most future-proof solution.

Service & Training

We are now a technology-as-a-service company, growing to respond to new challenges with a disruptive business model, designed to grant customers a focus on what really matters: their core business.

We already provide several technological solutions as-a-service, so that we can reduce financial impact and make lifecycle management hassle-free for our clients.