CatEMission is leading-edge in designing and manufacturing advanced Catalysts.

We also sustain environmental innovation with the development of specific catalytic solutions to address the emerging pollutants coming from novel fuels, such as LNG, ammonia and methanol.

CatEMission catalytic product range includes oxidation catalyst (DOC), Diesel Particulate Filter (DPF), and Selective Catalytic Reduction (SCR) technologies. Our emission system solutions cover the needs of different sectors: from off-road to construction, from industrial to marine sectors.

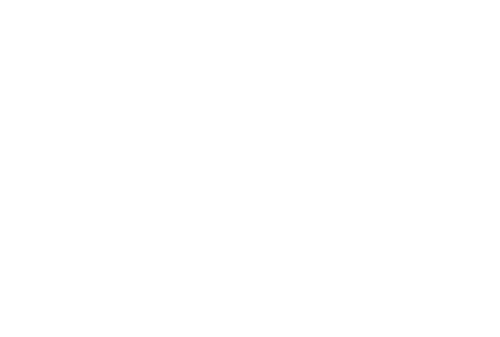

Cemnox technology, overcomes the traditional challenges of SCR technology with a compact and highly effective solution for engines up to 1.6MW, and scalable configurations for larger applications. Compact SCR does not need an injection duct or compressed air. As a result, the system could be more than 2 time shorter in lenght in comparison to the standard SCR.

The CatEMission cemNOx SCR system is a state-of-the-art solution for selective catalytic reduction, utilizing advanced DeNOx catalysts to efficiently reduce NOx emissions in exhaust gases. It is engineered to work across a wide range of temperatures, with a urea solution injection process optimized for both general and marine applications, without limitations in the amount of gas flow and temperatures.

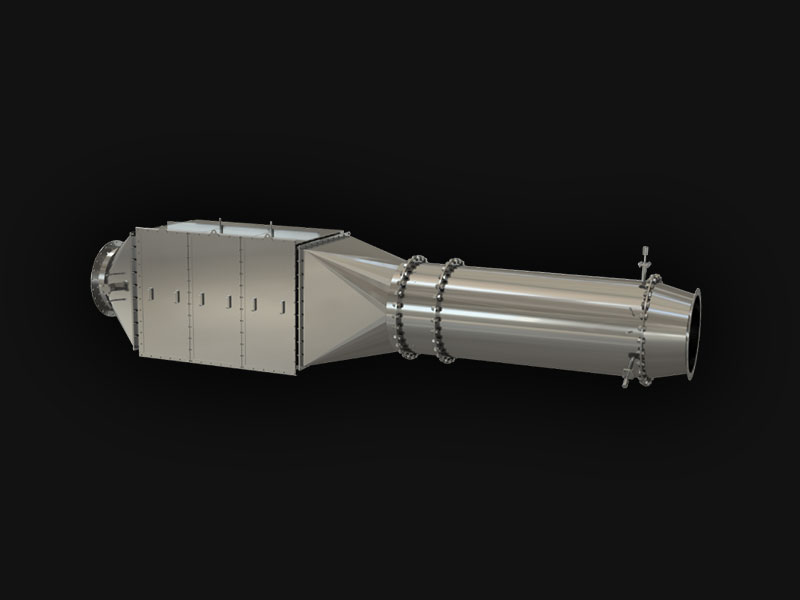

The Diesel Oxidation Catalyst (DOC) system is a cutting-edge solution for significantly reducing harmful emissions from diesel engines. The system employs a honeycomb catalytic converter that promotes the oxidation of exhaust gas components, ensuring cleaner emissions effectively reducing harmful pollutants such as CO, HC and VOC.

The CatEMission Diesel Particulate Filter (DPF) is an essential component for the reduction of particulate matter in diesel engine exhaust gases. It operates through physical filtration, employing a honeycomb filter design made from Ceramic or Silicon Carbide system. Moreover, a special chemical coating allow its thermal self-regeneration at low temperature.

The CatEMission Methane Slip Catalyst system is an innovative solution designed to address methane slip, a potent greenhouse gas, from gas and dual fuel engines. Leveraging catalytic oxidation technology, this system is pivotal in significantly reducing methane emissions in marine and industrial applications.

R&D activities are crucial to our technology’s development.

Our research began with the study of oxidative catalysts for methane in the automotive sector and progressed with specific studies conducted in our own laboratory.

Currently our R&D is focused on validating the methane slip technology in the marine field through ongoing tests, addressing the market’s need to reduce environmental impact.

Simultaneously, a new area of research is underway exploring a range of catalysts specifically designed for emerging pollutants. This includes the abatement of N2O from ammonia-fueled engines and the reduction of formaldehyde from methanol-fueled engines.

Recognizing that black smoke emissions are becoming a critical issue, particularly in ports, and that no existing technology can effectively remove smoke from large engines using polluting fuels, CatEMission is developing a clever, compact and clog-resistant solution that can remove the visible portion of the smoke.

Thanks to the internal expertise in process design and catalysts formulation we create each system according to customer requirements.

We also conduct CFD analyses as needed to validate the basic design.

From the winding of the metal substrates to the coating and fabrication of full-scale reactors.

We manufacture each system directly in our production facility in Italy.

Recycling means thinking the life cycle of the catalytic converter through to the end.

After the operating life of the catalyst, CatEMission can recover the precious metals (PGM), thus allowing for a cost reduction compared to the first supply.

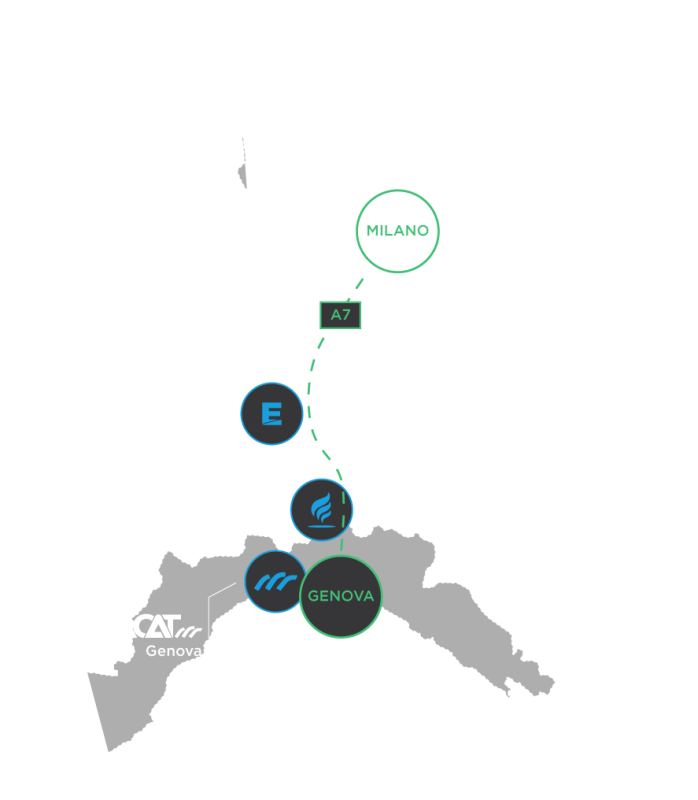

CatEMission is a company jointly owned by Ecospray Technologies, a specialist in engineering, and Itacat, an expert in catalyst technology.

This strong partnership and blend of expertise provide CatEMission with a distinctive market advantage, offering a full spectrum of services—from concept design to production—and the ability to customize technologies to meet market needs.

Ecospray Technologies is a leader in zero-emission engineering for the marine and industrial sectors.

Itacat is one of Europe’s leading manufacturers of emission control products.

Via Orti 61 – 16017, Isola del Cantone (GE) – Italy

+39 10 726 16 53

info@cat-emission.com