Natural Gas Liquefaction

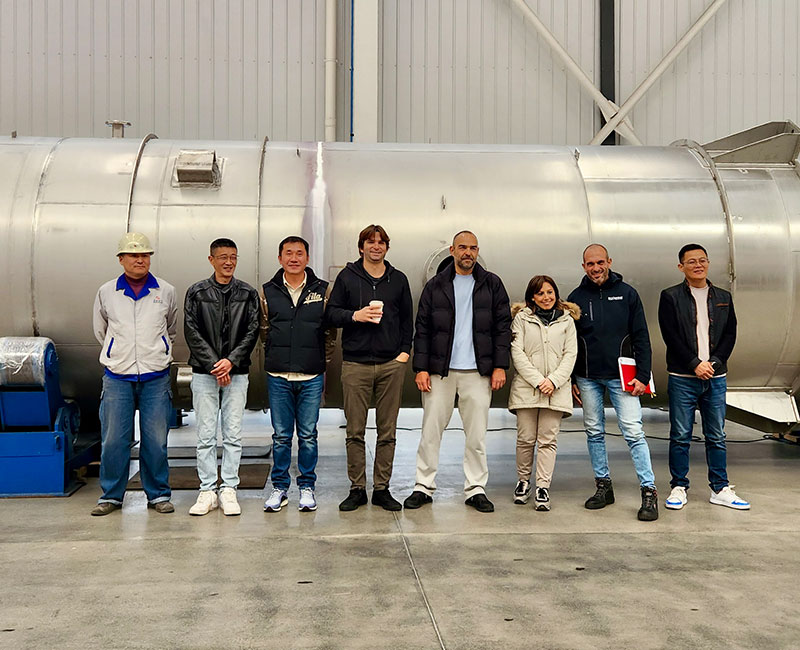

Ecospray offers modular, on-site gas liquefaction and separation systems that recover waste gases such as flare or associated petroleum gas (APG). These solutions support the creation of virtual LNG pipelines, eliminating the need for large storage terminals and reducing logistics costs, emissions, and operational risks.

The core of the system is a cryogenic chiller that uses reverse Brayton closed-cycle technology. The NG liquefaction system is scalable and customizable for applications like bunkering, power generation, or transport. Each module can produce:

- 9.5 tons/day of LNG at -160°C, processing 550 Nm3/h or 0.5 MMSCFD

- 12.0 tons/day of LNG at -150°C, processing 620 Nm3/h or 0.6 MMSCFD

Key Features:

- Compact & Modular: Containerized (40–45 ft), easy to transport and install.

- Reliable: No contamination risks due to separation of cooling media (nitrogen) from the gas stream.

- Efficient: Moderate energy use with primary costs from power consumption.

- Flexible: Adjustable output down to 40% and customizable LNG specs

- Safe: Self-generated nitrogen cooling reduces fire/explosion risk.

- Complete: Equipped containers with insulation, lighting, HVAC, and ventilation.

- Unmanned: Remote monitoring and control, with web access and data storage for maintenance and alarms.