Rise Above Market Challenges with Future-Proof Technologies

Our solutions for the future challenges of the maritime industry rely on three pillars: Decarbonization, IoT & Digitization, and Technology as-a-service. Discover Ecospray’s innovation line-up for 2021 and beyond.

Ecospray: a clear vision for a cleaner future

From Clean Shipping International, Spring Edition 2021

“The past year has redefined the rules, causing us to face a turnaround of our previsions. The maritime industry is not only dealing with a crisis due to the pandemic, but is growing and adapting to new challenges, preparing for the future: 2050. […]

Ecospray chooses relayr to revolutionize the Maritime Industry with Artificial Intelligence powered solutions

The partnership between Ecospray and relayr will allow the creation of a new generation of emission control systems: the smart scrubbers. […]

Filtration

Discover all solutions powered by CatEMission

Meeting the EGCS challenges

From Clean Shipping International, Winter Edition 2020

“Ecospray has always been involved in the development of a wide variety of environmental solutions for many different industries, […]

Beyond compliance, new Marine solutions

From Clean Shipping International, Autumn Edition 2020

Ecospray Technologies is a well-known name in the marine industry, but these days, it is probably best known for its scrubbers. We prefer to call them Advanced Air Quality Systems […]

Together along a journey of environmental transformation

From Clean Shipping International, Spring Edition 2020

“The entire shipping industry is undergoing deep change — an environmental transformation […]

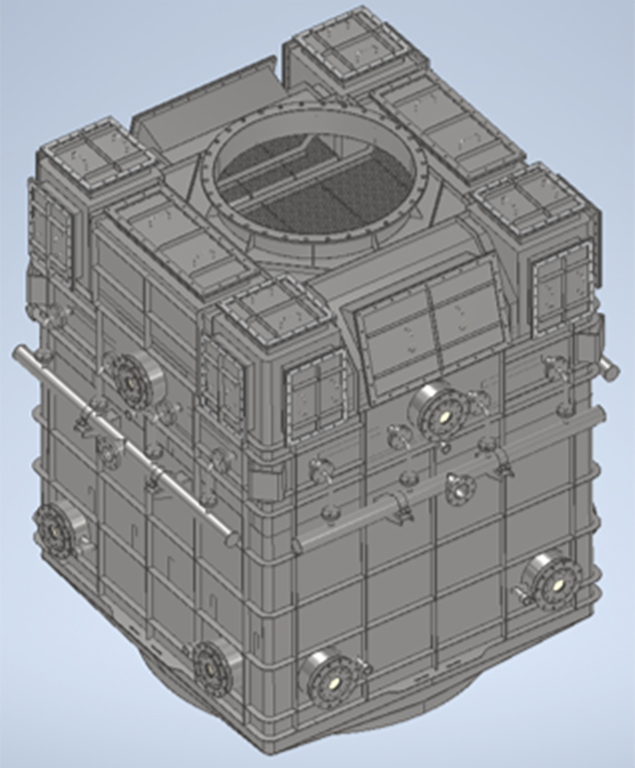

Wet Electrostatic Precipitator

The importance of environmental and health related issues has been steadily increasing, as has the demand for pollution reduction – particularly in relation to the upcoming regulations on dust and particulate matters emissions. Our WESP […]

Filter cassettes

The multi-pollutant axial flow filtration cassettes (Wall flow/Flow through) combine the oxidation of CO (thanks to special oxidative catalysts) with the particulate removal and NOx abatement. These cassettes are suitable for any industrial application (for […]

Diesel Particle Filtration

Complying with the most stringent international emission regulations, Ecospray provides the latest generation of filtration systems. Our Diesel Particle filters allow for the removal of soot, ash and particulate matter, heavy metals, aromatic hydrocarbons (PAH) […]