Decarbonization through bio-LNG

Former German President Christian Wulff inaugurated Germany‘s first compact plant to produce bio-LNG from biomethane in Darchau on August 9, together with the board of the Darchau Agricultural Association. Attended by more than 300 people, […]

A new order for three plants in Italy for the production of Bio-LNG directly from biogas produced on site.

Ecospray confirms its positive trend in the renewables sector with a new collaboration in Italy, with a primary actor in the energy sector. Focused on the realization of a series of projects for the decarbonization of transport […]

Ecospray and Ruhe Company Group: new agreements for Biomethane Micro-Liquefaction and CO2 liquefaction projects.

Ecospray and Ruhe intensify their joint work towards climate goals with new agreements to build two plants for bio-LNG production and three CO2 liquefaction systems. Italy’s Ecospray and Germany’s Ruhe signed new agreements for the […]

New fuels, renewable sources and sustainable mobility: Ecospray hosts the E-CO2 project

On the 29th of September 2021 Ecospray hosted a delegation of partners of the E-CO2 project – companies, experts, representatives of the institutions and the Municipality. During the day, organized as part of the E-CO2 […]

Liquefaction

Landfill Biofuel: in Novi ligure BIO-LNG is produced from waste

Installed at the SRT landfill in Novi Ligure, our high-tech production plant produces BIO-LNG and is a virtuous example of a circular economy and respecting the environment.

Currently in commissioning phase, our system transforms the waste from the Novi Ligure landfill into clean fuel […]

Nitrogen Rejection Unit

This system processes LNG with an excessive concentration of nitrogen (whose calorific value is not suitable for utilization) by separating the nitrogen (and oxygen in excess) from the LNG. Based on cryogenic separation/distillation, the process […]

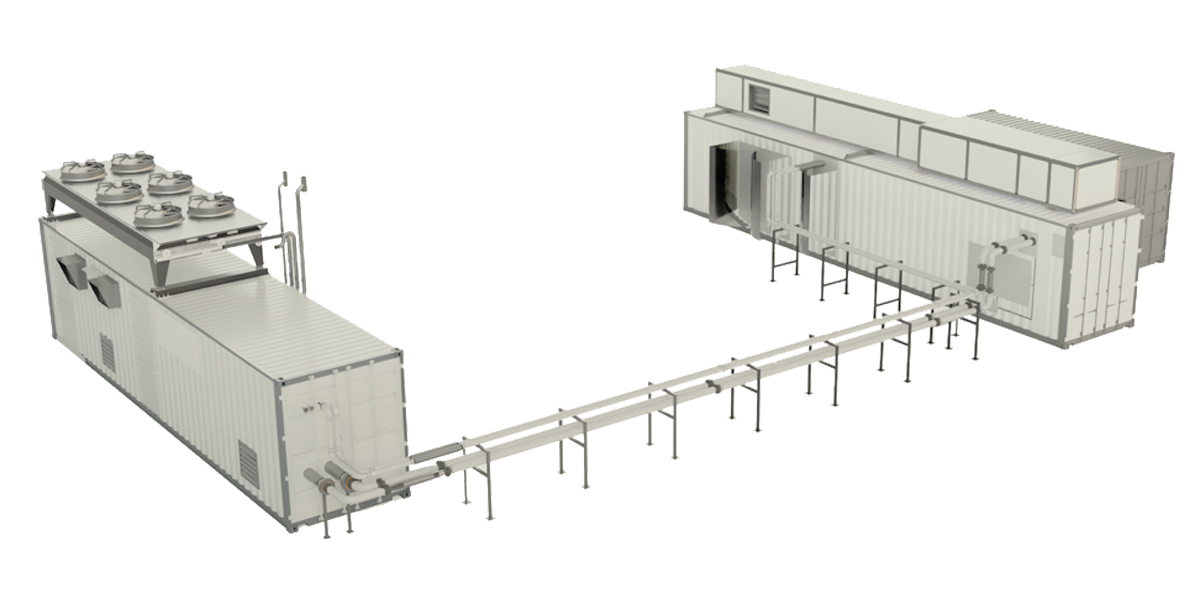

Biomethane Liquefaction

Ecospray provides solutions for the liquefaction of biomethane (bio-LNG) into high-quality fuel for road and marine transportation. The Ecospray micro-liquefaction systems are modular, enabling any existing biogas plant to be converted into a system that […]

Natural Gas Liquefaction

Our micro-liquefaction systems enable on-site LNG production directly from the pipeline. In addition, Ecospray systems can convert a waste product, such as flare gas or APG (associated petroleum gas), into a resource, as NGL and […]