Installed at the SRT landfill in Novi Ligure, our high-tech production plant produces BIO-LNG and is a virtuous example of a circular economy and respecting the environment.

Currently in commissioning phase, our liquefied biomethane – BIO-LNG, production plant transforms the waste from the Novi Ligure landfill into clean fuel.

It’s a highly innovative plant, and one of the first of its kind in Italy.

It is, in fact, the first system to use an innovative patented technology which treats the biogas produced from landfills during their cultivation and management phases, purifies it and manages its subsequent liquefaction for use as automotive fuel.

Capable of producing 1 tonne of BIO-LNG per day – which is equal to approximately 5,000 km of travel with zero emissions – this may be proposed as an alternative method to take advantage of landfill biogas, as opposed to its traditional use in the production of electricity.

A Project That Embodies a Circular Economy

We strongly believe in this project because our goal of minimizing the environmental impact of industrial production, and making mobility more sustainable, has always driven Ecospray in its search for innovative technological solutions. Furthermore, by adopting a new method to manage resources and waste, we are responding to the demands of the energy market in the best way possible.

This project fits perfectly into the logic of a circular economy, whereby Ecospray positions itself as a unifying company which transforms the waste produced by a series of supply chains – and its potential damage to the environment – into a product that can be used by a series of others.

In fact:

- We source our supplies from the economy rather than from nature reserves

- We add value to existing products and materials, even those that are considered refuse

- We create further value beyond our direct customers

The implementation of the project guarantees several advantages to stakeholders – both from an economic and environmental perspective: not only will it be possible to avoid travelling hundreds of kilometres to obtain supplies with LNG fossil fuel, but above all it will become possible to use locally produced bio-fuel, with consequent reductions in the environmental impact of the procurement process itself.

Partnership as a Growth Strategy

This project demonstrates how a collaboration between companies and entities in this sector can represent not only the implementation of a circular economy (transforming waste into a viable resource) but also serves as a tangible example of a sustainable economy where local companies are involved and benefit from the partnership.

SRT S.p.A., a public company which is owned by 115 municipalities in the lower eastern Piedmont area, manages the waste enhancement, treatment and disposal plants in Novi and Tortona, and is our key partner in terms of raw material acquisition.

In the headquarters of the Municipality of Novi Ligure, the region which houses our first demonstration plant, the SRT proposal was received with a very proactive attitude, as it solved the urban planning problems related to the use of the land adjacent to the landfill, and demonstrated that it takes into account the choices made by the public company of which it is the largest shareholder.

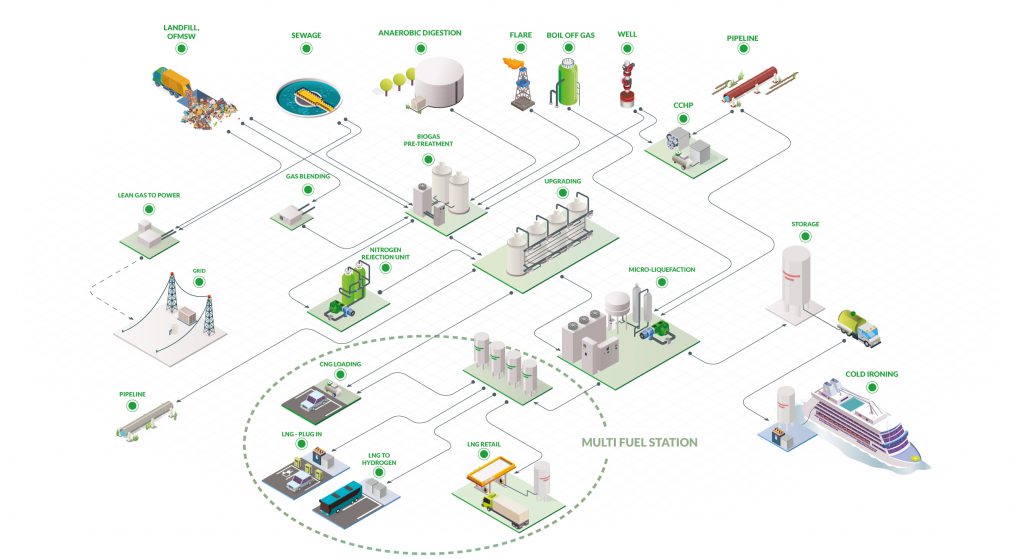

The system, designed and built by Ecospray, is an integrated process, starting from the withdrawal of the biogas from the landfill to the loading of the finished product, BIO-LNG, in a cryogenic tank to then be marketed.

The company SO.GE.DI – Fratelli Ratti – which will market the liquid biomethane produced to the public, has joined the project with the same enthusiasm that has brought them to be among the first in Italy in the distribution of liquid methane in its L- CNG stations (capable of delivering both liquid and gaseous methane) located in Novi and Tortona – and represents the new frontier of distribution to the transport industry, the final brick that unifies the entire supply chain.

Our Background

At Ecospray, we manufacture compact turn-key systems for the pre-treatment and advanced upgrading of biogas from agricultural plants, FORSU, water purification sludge and landfills for feeding into the network and biomethane micro-liquefaction systems.

Furthermore, we also build systems for the exploitation of biogas / off-gas – up to 2% methane – for the production of electricity and heat and conversion systems to produce hydrogen and energy with fuel cells directly from LNG.

With a 360° approach, we follow our customers starting from the initial feasibility study up to after-sales services with the possibility of financing and / or pay-per-use payments for full service contracts.